An ejector is a device used to suck the gas or vapour from the desired vessel or system. An ejector is similar to a vacuum pump or compressor. The major difference between the ejector and vacuum pump or compressor is it had no moving parts. Hence it is relatively low-cost and easy to operate and maintenance-free equipment. Ejector Working Principle. Most ejectors have a fixed capacity curve as shown in Figure 1. In this type of ejector the capacity is a function of the absolute pres-sure at the suction inlet. Increasing the steam pressure above the design pressure will not increase the capacity of the ejector: as a matter of fact, it will actually decrease the capacity because of the. Ejector Design Calculation Software Online Gas Ejector Design Calculation The basic SI unit of force is the newton, which has the symbol N.One newton is defined as the force necessary to give a mass of 1 kg an acceleration of 1 m/s2.

- Calculations for. They are especially effective in the chemical industry where an on-site supply of steam ejector calculation Free Download, steam ejector design software, steam. Do you need an ejector design done for you? Ezejector can size and specify ejectors for a wide range of applications.

- Ejector Design Calculation Software Online Gas Ejector Design Calculation The basic SI unit of force is the newton, which has the symbol N.One newton is defined as the force necessary to give a mass of 1 kg an acceleration of 1 m/s2.

Please complete the form below to request Graham software on CD.

Choose our Vacworks II Selection Software Suite or SealCool Software.

Vacworks II Selection Software Suite

Vacworks II is a selection software suite developed by Graham engineers that enables you to select ejector systems or ejectors in combination with liquid ring vacuum pumps. You are able to select up to a four-stage ejector system, with or without a precondenser, that includes either surface type or direct contact inter and after condensers. The software will provide you with utility consumption, equipment size, and drawings of the individual components. It also includes useful tools for estimating vapor pressures of different organic or inorganic compounds, calculating hydraulic losses in piping systems under vacuum, determining the proper tail leg height for a vacuum condenser, a calculation routine for converting between mass and volumetric flow rate, and a conversion utility for converting between different units of measure.

Vacworks Software:

- Vacuum System Design

- Thermal Compressor Design

- Conversion Calculator

- Steam Mollier Data

- Vapor Pressure Database

Vacuum and Heat Transfer Technical Articles

Multimedia Presentation

SealCool Software

Our SealCool software assists in sizing our Heliflow Heat Exchangers.

In this article, we will see the Ejector Working Principle

What is Ejector?

Ejector Design Calculation Software Free

An ejector is a device used to suck the gas or vapour from the desired vessel or system. An ejector is similar to a vacuum pump or compressor. The major difference between the ejector and vacuum pump or compressor is it had no moving parts. Hence it is relatively low-cost and easy to operate and maintenance-free equipment.

Ejector Working Principle

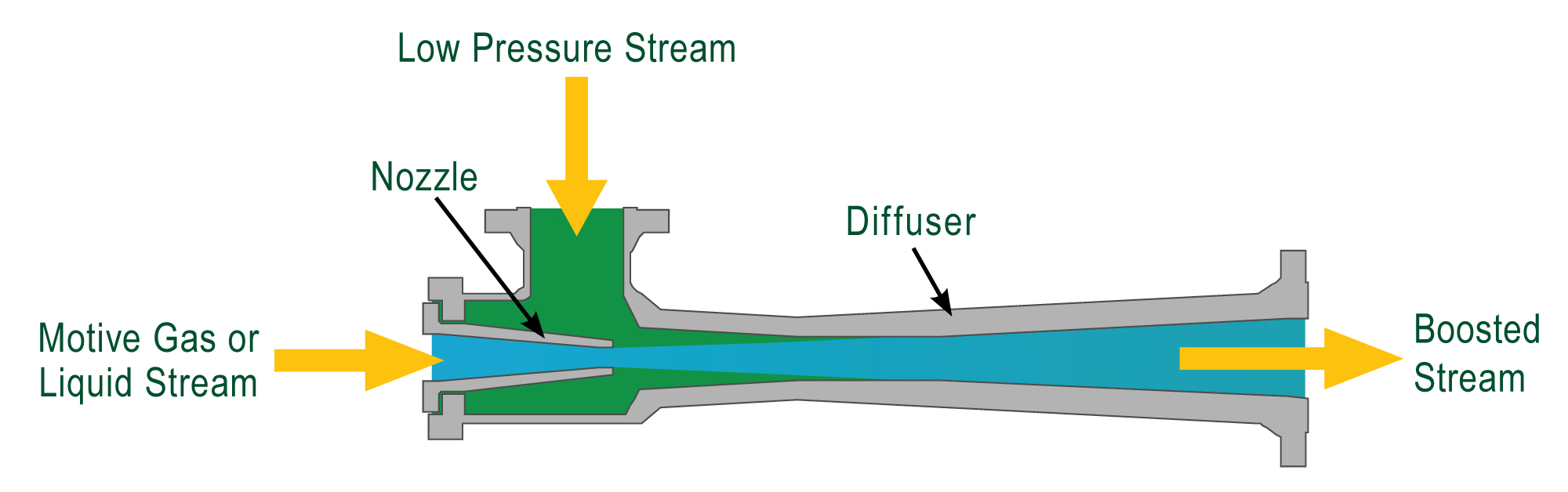

The operating principle of the ejector is the pressure energy in the motive fluid is converted to velocity energy by an adiabatic expansion in the Converging/Diverging

The operating principle of the ejector is the pressure energy in the motive fluid is converted to velocity energy by an adiabatic expansion in the Converging/Diverging Nozzle. Due to the pressure drop of the motive fluid, it will create a low-pressure zone before the mixing chamber. Due to the low-pressure zone, the suction fluid will start to move toward it and mix with motive fluid in the mixing chamber. In mixed fluid enter the diverging portion of the ejector where its velocity energy is converted into pressure energy.

Working of Ejector

The suction line of the ejector is connected to the vessel which is to the kept under low pressure. Refer to the below figure, a high pressure motivating fluid enters at “A” and expands through the converging-diverging nozzle to “B”. The motive fluid will create a vacuum in the mixing chamber refer to to the pressure curve where the pressure is decreased and velocity is increased. Due to this suction fluid “C” (air or gas) from the connected vessel moves toward the mixing chamber “D”. When the suction fluid starts to mix with the motive fluid in the mixing chamber. The velocity of the fluid at the mixing chamber is approximately 600 to 900 meters per second.

Then the mixture travels through the diffuser “E”, its velocity energy is converted into pressure energy. Thereby the mixture gained higher pressure send to the atmosphere or some closed system. Normally the discharge pressure will be 10 to 15 times of the suction pressure

Capacity of Ejectors

The capacity of an ejector is determined by its dimensions. By the required capacity is very high then two or three ejectors are working in parallel. if greater compression is required, two or more ejectors will be arranged in series.

Ejector Installation

Ejector Design Calculation Software Tutorial

Ejectors may be installed at any orientation. However, it is very important to provide a provision to remove the condensate or solid particles from the entrained gases of an ejector. Since any condensed or solid particles may reduce the throughput capacity of the ejectors.

Hence it very important to provide a drain valve installed at low points can be either manual or automatic float operated valves.

Another important thing to check during ejector installation is external loads(Piping load) act on the ejectors. Since any misalignment will adversely affect the performance of ejector.

Ejector Benefits

- Ejectors can be operated with many different motive fluids: steam, air, organic vapour and other gases.

- No moving parts, no lubrication, no vibration. Hence low maintenance cost when compared with other peer equipment.

- Ejectors can be installed indoors or outdoors without restriction.

- Can be installed at any orientation. Hence space requirement will be very low.

- The initial cost is very less and no spares required.

- Easy to handle corrosive and slugging liquids.